|

|

|

The basic theory of hydrogen recovery system

|

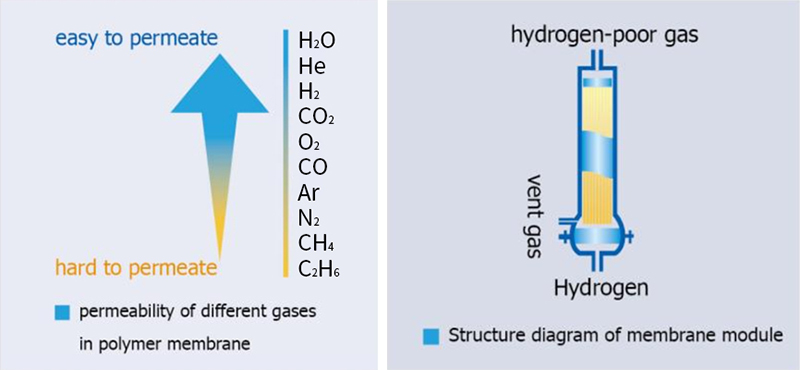

When two or more than two mixed gases pass through membrane, the permeant rate of different gases are diverse because of their solubility and diffusion rates difference. Under the impetus----pressure difference between two sides of membrane, gases whose permeant rate are comparatively quick, for example water vapor, hydrogen, helium and carbon dioxide, etc. pass through to the other side of membrane and enriched first; while gases whose permeant rate are low, for example methane, nitrogen and carbon monoxide stay and concentrated. The mixed gases are separated.

|

|

|

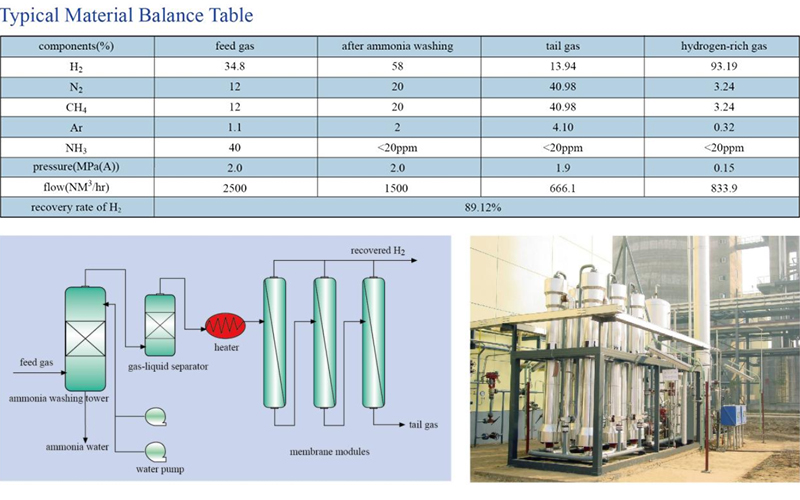

Recovery system of Hydrogen with membrane technology from purge gas in ammonia synthesis process

|

TBM solely holds hydrogen recovery membrane technology in China.

Characteristics of performance and applications

●The recovered concentration and recovery rate of hydrogen are both up to 90% with one-stage hydrogen recovery unit. When with two-stage unit, the data are up to 99%.

●Max. operation life of the membrane: 10 years.

●Low energy consumption. Producing one ton of ammonia can save 40kwh electricity.

●Increase 4-5% ammonia production.

●Small occupied area. Easy installation and operation.

●By-product: 10-20% ammonia water when using high-pressure water to wash the purge gas.

●Applied to more than 300 ammonia plants.

|

|

|

Recovery system of Hydrogen with membrane technology from off-gas in oil refinery process

|

Applications

●Concentration of H

2 from Catalytic Reforming Gas

●Recovery of H

2 from Hydrofining Tail Gas

●Recovery of H

2 from Hydrocracking Tail Gas

●Recovery of H

2 from Residue Catalytic Cracking Gas

●Recovery of H

2 from PSA Desorption Gas

Characteristics of performance

●High H2 recovery rate, and the recovered H

2 concentration is up to 99%

●Wide applications under high\medium\low differential pressure and various processing capacities.

●Simple process with small occupied area. Easy installation and operation.

●Max. operation life of the membrane: 10 years.

●Rich experiences with more than 40 systems

|

|

|

Application of membrane separation technology in methanol industry

|

Characteristics of performance

●Total recovery rate of H

2, CO, CO

2 is up to 90%

●Low energy consumption. Reducing the usage of natural gas and increasing 2-3% of methanol production. Producing one ton of methanol can save 30kwh electricity.

●Wide applications under high\medium\low differential pressure.

●Room temperature operation with zero consumption of other energy. Friendly to environment.

●Easy to combine and expand.

|

|

|

Recovery of H2 from purge gas of ammonia tank with low pressure membrane technology

|

Characteristics of performance

●Low operation pressure: 2.0MPa, 1.6MPa, 0.9MPa.

●H

2 recovery rate and recovered H

2 concentration are above 90%.

●Small occupied area. Easy installation and operation.

●18% ammonia water can be recovered at the same time.

●Good ammonia-resistant capacity (the maximum ammonia concentration is 200ppm).

●Max. operation life of the membrane: 10 years.

●Short investment payback period of 5-6 months.